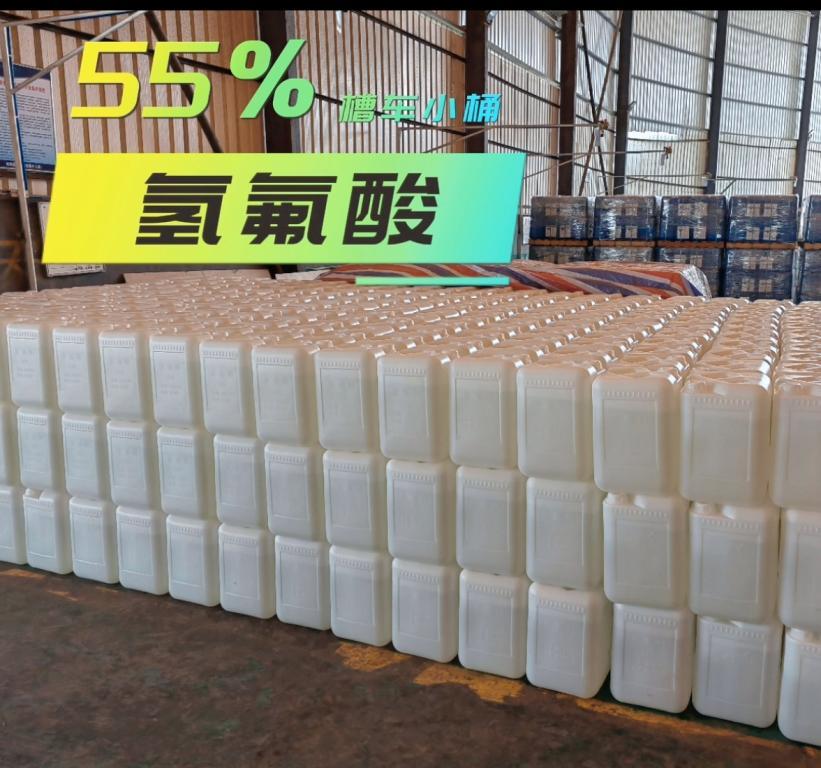

Hydrofluoric acid

Contact Info

- Add:, Zip:

- Contact: 段先生

- Tel:13826066669

- Email:6269453@qq.com

Other Products

Product Introduction: Hydrofluoric acid is a potent inorganic acid primarily used for glass etching, metal cleaning, and silicate analysis. Its unique chemical properties enable it to react with various substances to achieve specific process effects.

Product Advantages: Hydrofluoric acid exhibits strong reactivity and etching capabilities, allowing for rapid and precise etching of glass surfaces. It is also effective in cleaning and treating metal surfaces, enhancing cleanliness and roughness. Additionally, its stable chemical properties ensure efficiency and reliability in specific applications.

Product Uses: Hydrofluoric acid is widely applied in semiconductor manufacturing, optical glass processing, metal surface treatment, and scientific research experiments. Whether for precise circuit board etching or fine processing of optical lenses, hydrofluoric acid plays a unique role in achieving high-precision and high-efficiency production goals.

The common concentration of hydrofluoric acid solution is 40%. Commercially available hydrofluoric acid is mainly categorized into industrial-grade and electronic-grade. While both generally have the same concentration, their applications differ due to purity variations. Industrial-grade hydrofluoric acid, with relatively lower purity, is suitable for metal pickling and glass etching. In contrast, electronic-grade hydrofluoric acid, with higher purity typically exceeding 99.9%, is extensively used in semiconductor manufacturing and the production of other high-precision electronic components.

Due to its ability to dissolve oxides, hydrofluoric acid plays a crucial role in the purification of aluminum and uranium. It is also used to etch glass for carving patterns, marking scales, and inscriptions. In the semiconductor industry, it removes oxides from silicon surfaces. In refineries, it serves as a catalyst for the alkylation of isobutane and n-butene. Hydrofluoric acid is also employed in the "pickling" process to remove oxygen-containing impurities from stainless steel surfaces. Additionally, it is used in the synthesis of various fluorine-containing organic compounds, such as Teflon (polytetrafluoroethylene) and refrigerants like Freon. [1] Both hydrofluoric acid and molten sodium hydroxide can be used to remove glass coatings from microfilament surfaces. At room temperature, hydrofluoric acid takes approximately 150 seconds to remove a 10 μm thick glass coating, while molten sodium hydroxide requires about 10 seconds. When using molten sodium hydroxide to remove the glass coating, experiments are conducted within a temperature range of approximately 300-400°C. At this temperature, molten sodium hydroxide effectively reacts with the glass coating, rapidly breaking down its structure and completely removing it in about 10 seconds. The composition and structure of the glass are critical factors influencing the corrosion resistance of glass-coated pure copper microfilaments. Glass-coated pure copper microfilaments were prepared using melt spinning, and experimental studies were conducted on the removal of the glass coating. The corrosion behavior of the microfilaments in hydrofluoric acid and molten sodium hydroxide was evaluated, analyzing their corrosion resistance in strong acids and alkalis and exploring the corrosion mechanisms.

| Industry Category | Chemicals |

|---|---|

| Product Category | |

| Brand: | |

| Spec: | 30%-55% |

| Stock: | |

| Origin: | China / Guangdong / Guangzhoushi |