LDW Type Spiral Conveyor Screen

Price:Negotiable

Contact Info

- Add:江苏宜兴和桥创业园, Zip: 214211

- Contact: 吴建刚

- Tel:0510-87876970

- Email:87876970@163.com

Other Products

Description

Additional Information

|

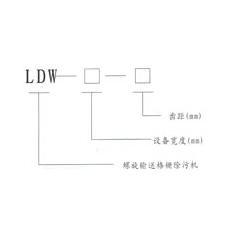

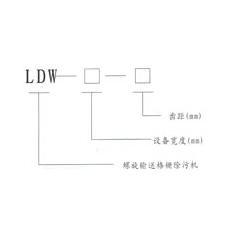

Overview and Application: The LDW type spiral conveyor screen decontamination machine is a new type of equipment developed by our company by absorbing and digesting advanced foreign technology and combining it with the specific actual conditions of water treatment projects in China. It is widely used for intercepting, conveying, and storing debris in urban and industrial sewage, as well as for the accumulation and transportation of screened waste in pump stations. Meaning of Model Specifications: Performance Features: 1. The LDW type spiral conveyor screen decontamination machine integrates the functions of screening, conveying, and screw pressing into one new product. 2. The entire machine has a compact structure, making it easy to install, operate, and maintain. 3. It occupies a small area, uses enclosed conveying, and does not cause environmental pollution. 4. This equipment can be equipped with a manual switch on-site or use PLC automatic control. Structure and Functional Principle: The LDW type spiral conveyor screen decontamination machine has a compact structure and an aesthetically pleasing appearance, with all components made of stainless steel. It can be fully automatically controlled, operates smoothly, has low energy consumption and noise, and features a small screen gap, generally designed to be less than 5mm. The equipment has high separation efficiency, and the cylindrical surface performs self-cleaning during operation, ensuring the screen never clogs. The equipment is installed at a 35° angle to the horizontal plane in a water channel. Sewage flows into the screen from the cylindrical end, exits through the side screen gaps, while debris in the sewage is intercepted by the circular screen bars. A toothed scraper rotates at a certain speed to push the screened residue into the collection trough inside the cylinder. Through the upper nylon brush and flushing water nozzle, the removed residue is conveyed, compressed, dehydrated, and discharged from the upper slag discharge hopper via spiral conveying. External Structure and Dimension Foundation Diagram: |

| Industry Category | Environment Industry |

|---|---|

| Product Category | |

| Brand: | |

| Spec: | |

| Stock: | |

| Origin: |